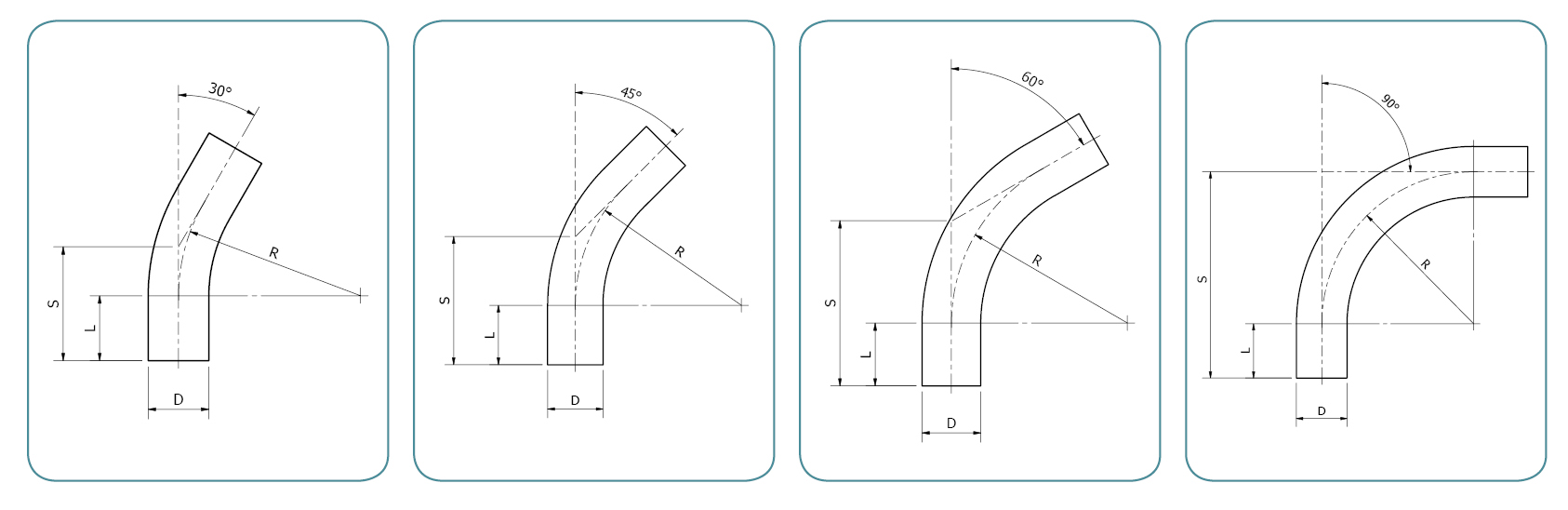

BENDS

ARC Bends™ Manufactured to:

- Angular tolerance of ± 5°

- Linear tolerance of ± 20mm

- Centre line of curvature

3 times the pipe diameter

Major Features:

- Improved roundness

- Seamless Smooth Interior

- No flow restriction

- Fully pressure rated

- Wearability increased in slurry lines

- Can manufacture any angles up to 90°

- Suitable for butt-welding, electrofusion or flanging

- Improved welding times

- Improved pumping efficiency

Industry Applications of ARC™ HDPE Sweep Bends

» Tailings

» Mines

» Paper Board Mills

» Chemical Works

» Water Supply – Treatment

» Fire Ring Mains

» Sewage – Gravity, Pressure & Vacuum

» Food Processing

» Thermal Generating Plants

» Steel Plants

» Hydro Generating

» Mechanical Contracting

» Saw Mills

» Civil Engineering

» Oil Refineries

» Irrigation

» Gas Distribution

» Conduit

» Coal Beneficiation

» Slurry Lines

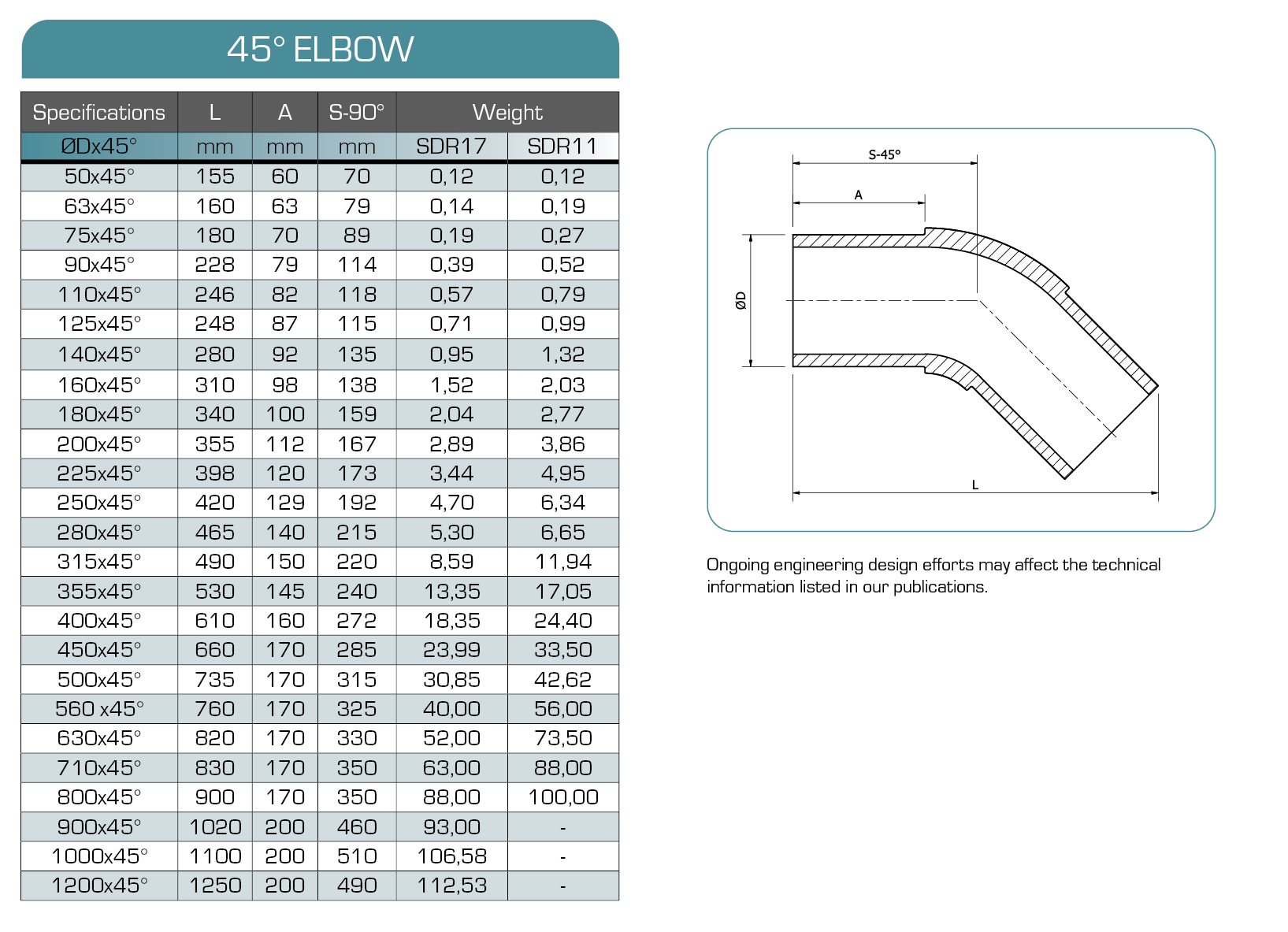

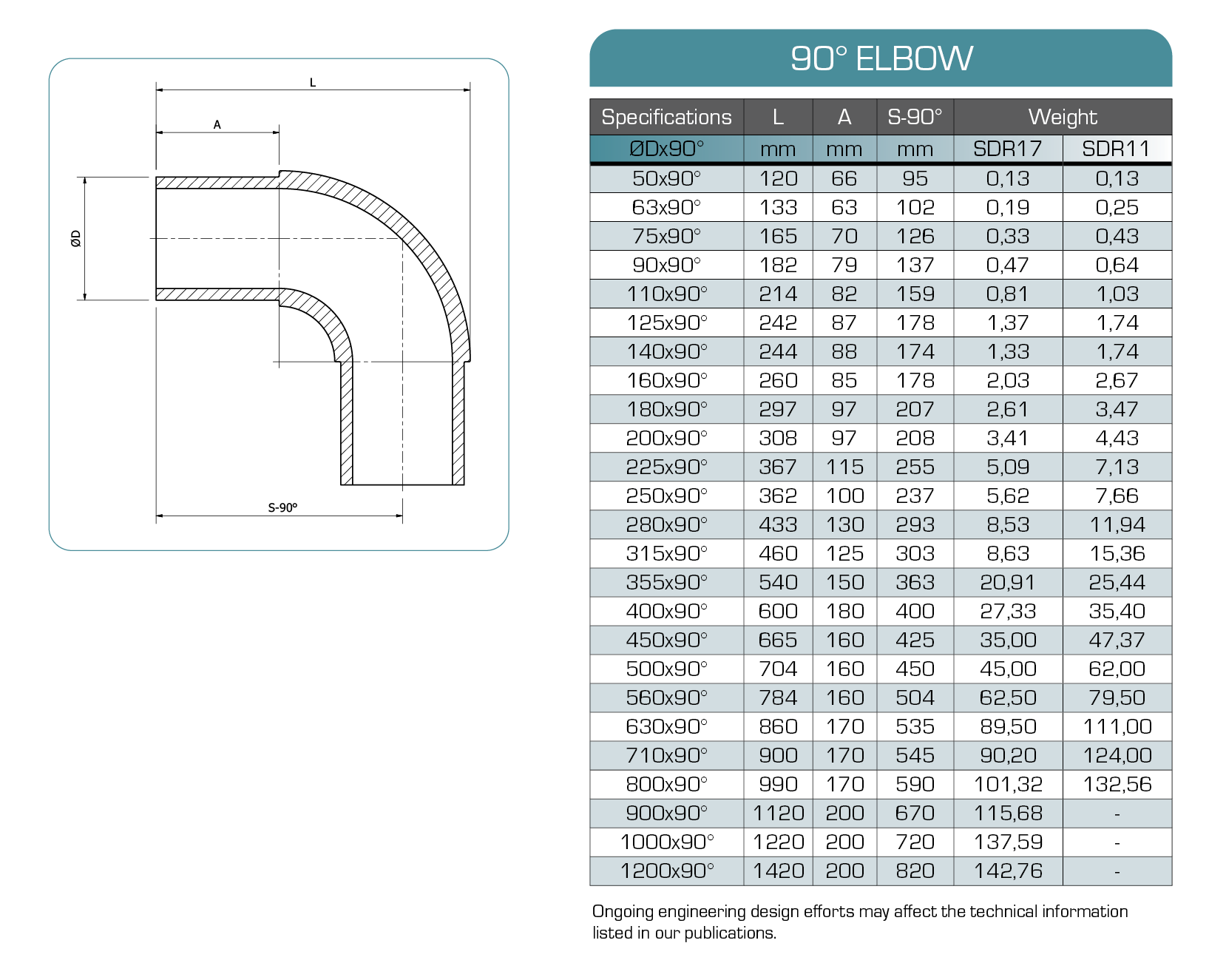

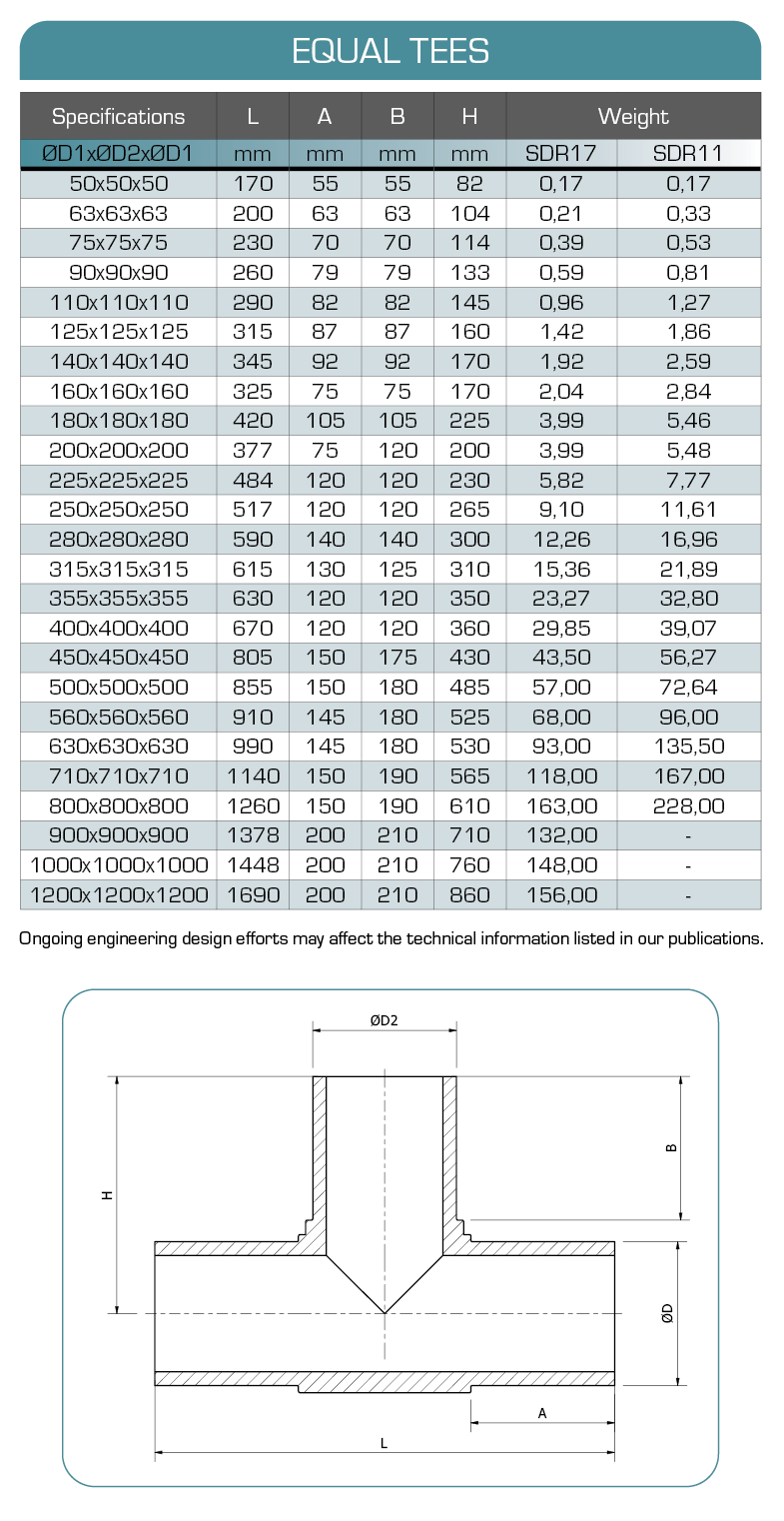

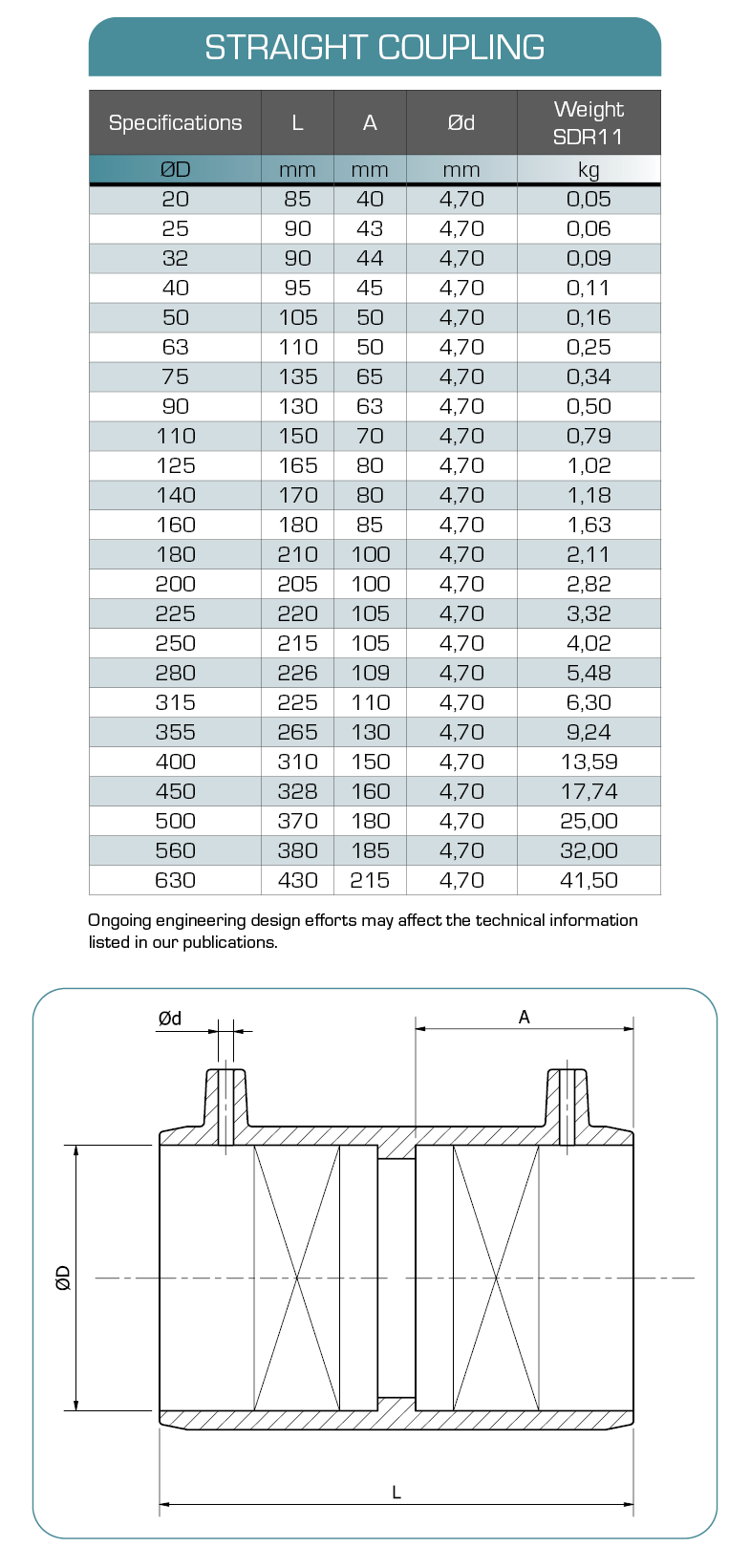

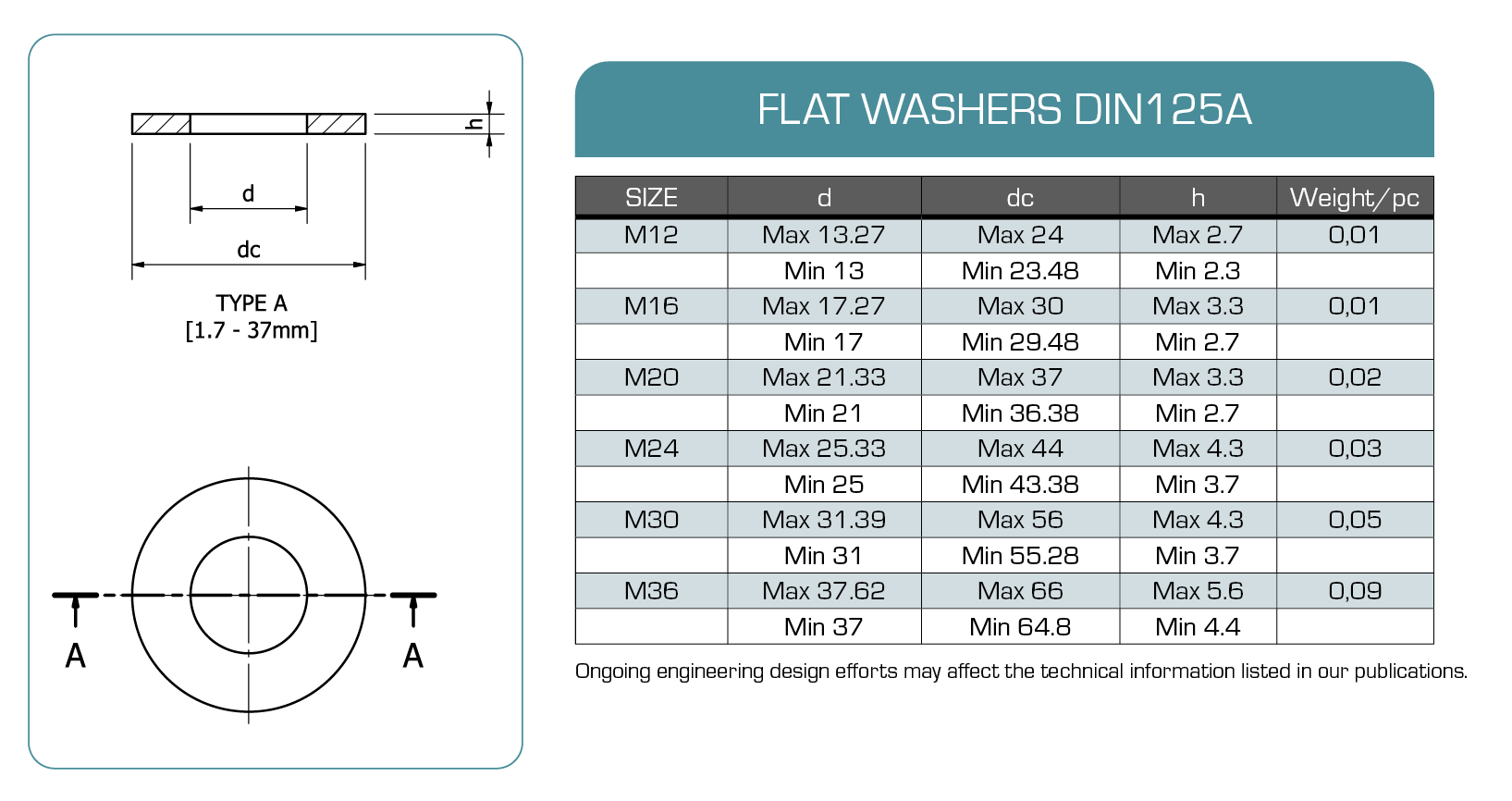

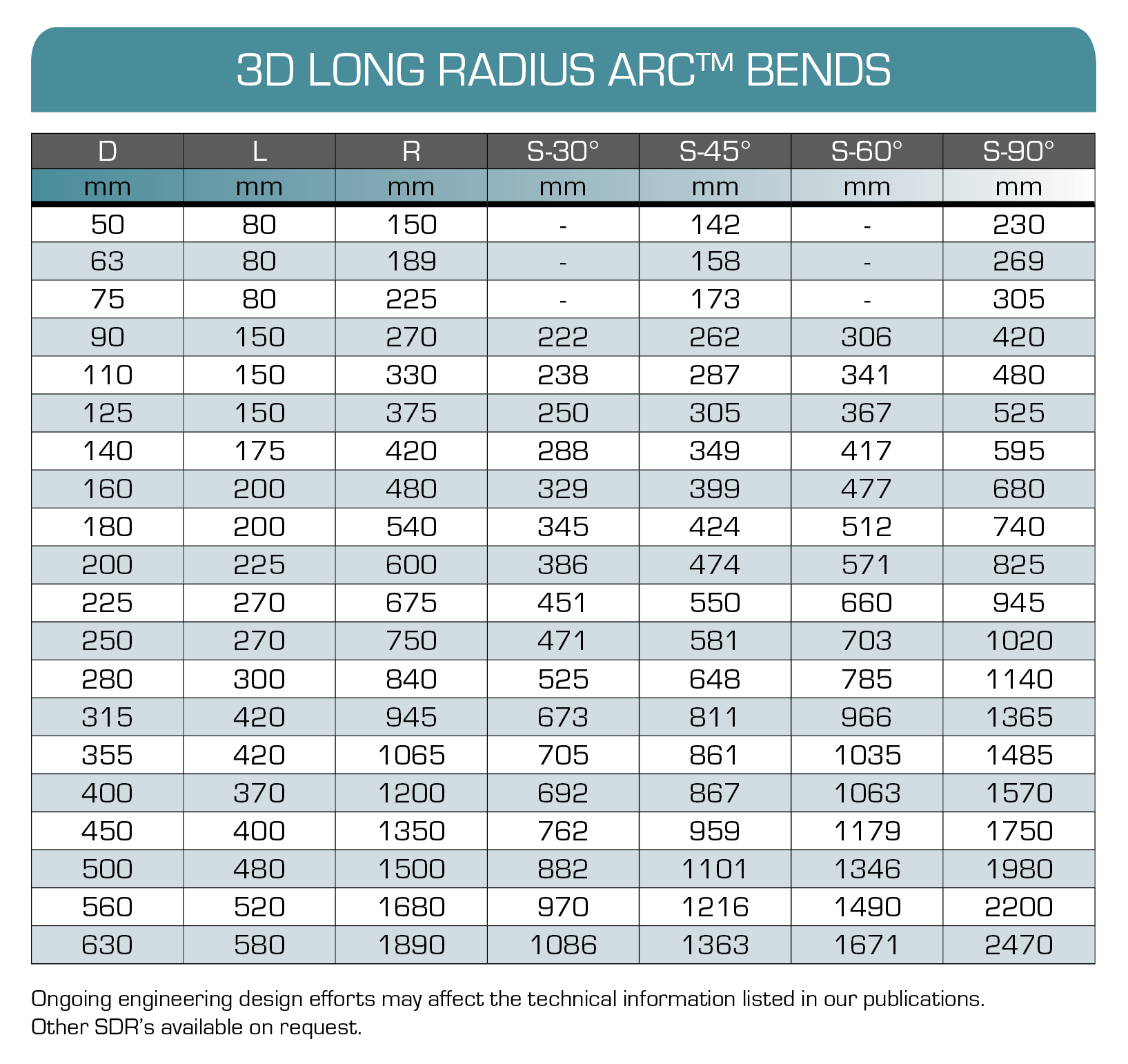

Long Radius Sweep Bend Specifications

SANS / ISO 4427 and SANS / ISO 4437

- Manufactured in one continuous piece from HDPE

PE 100 pressure pipe - Centre line radius of curvature 3 x diameter

- Meets Pipestar Africa published dimensional schedule. Dimensional tolerance ± 20mm

- Outside diameter of the spigot ends shall meet the requirements of ISO 4427/4437. Spigot lengths suitable for butt welding or electrofusion

- The bending process will result in a single piece bend at the angle specified by the engineer, with an angular tolerance ± 5°

- The bends will be shipped to site loose or palletized. No strapping or other foreign material will be placed inside the bend

- Fittings shall be examined for defects by visual inspection in the first instance, or by any other inspection method if required

- Bends should maintain roundness throughout curvature

- The manufacturing process shall not create any grooves, blisters, or other visual defects on the outside surface of the bend

- There shall be no cavities, voids or inclusions in the fittings body and the inside surface shall be smooth, clean and free from grooves or blisters

All fittings shall be clearly marked with at least the following information:

- Manufacturers name or Trade mark

- Identification of the material type

- Designated angle of bend

- Outside diameter, SDR and angle of the pipe for which the fitting is intended

- Raw material batch traceability

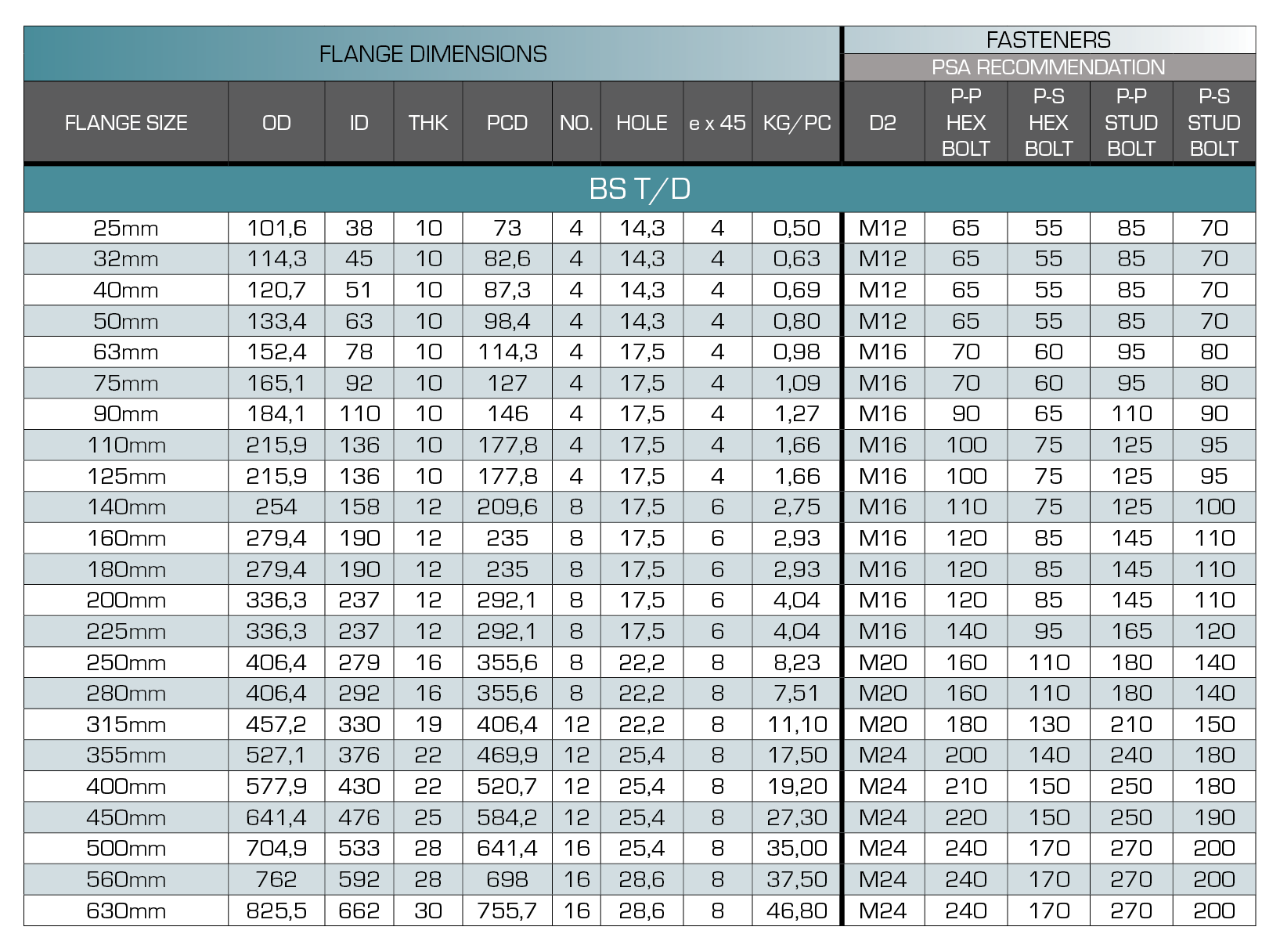

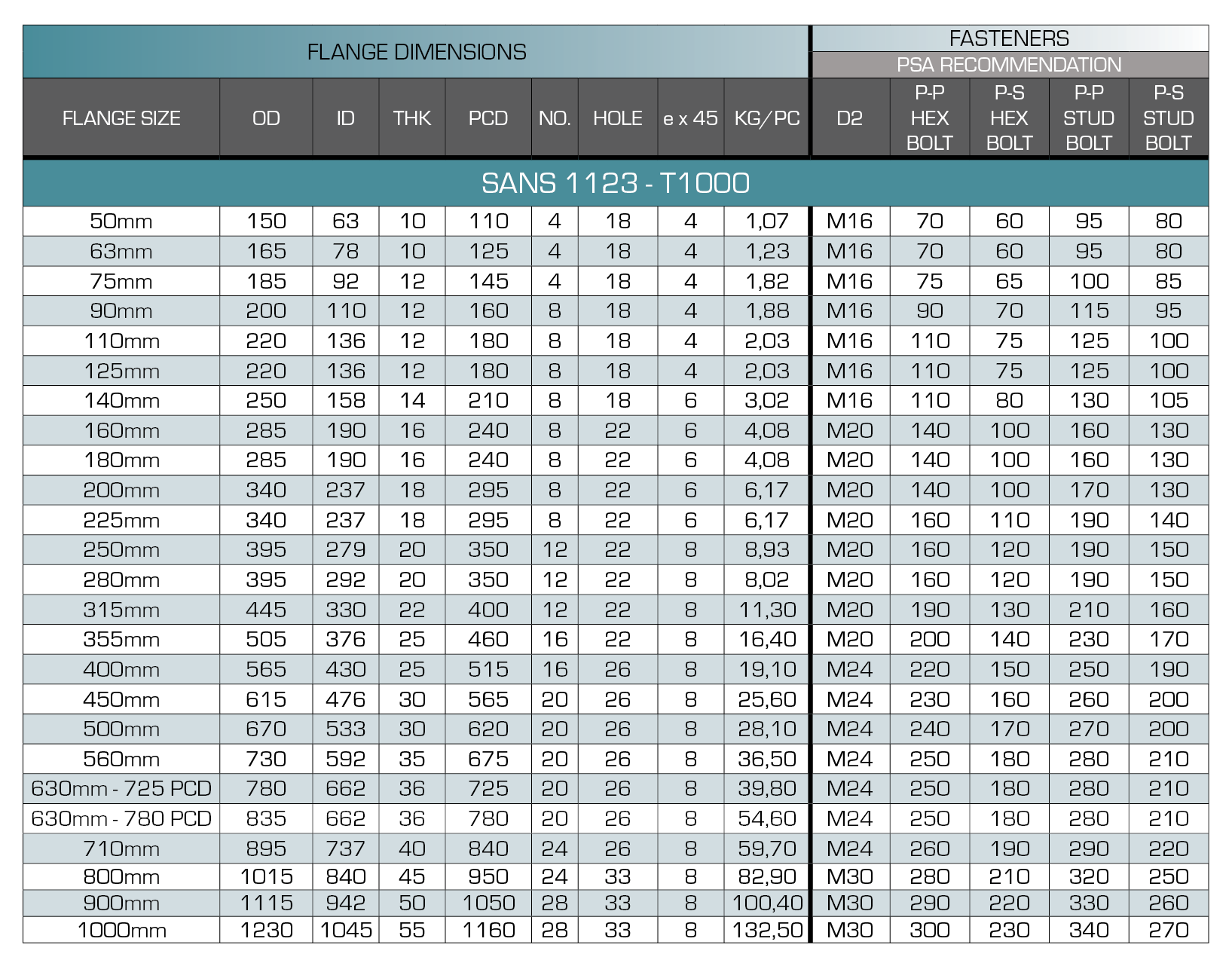

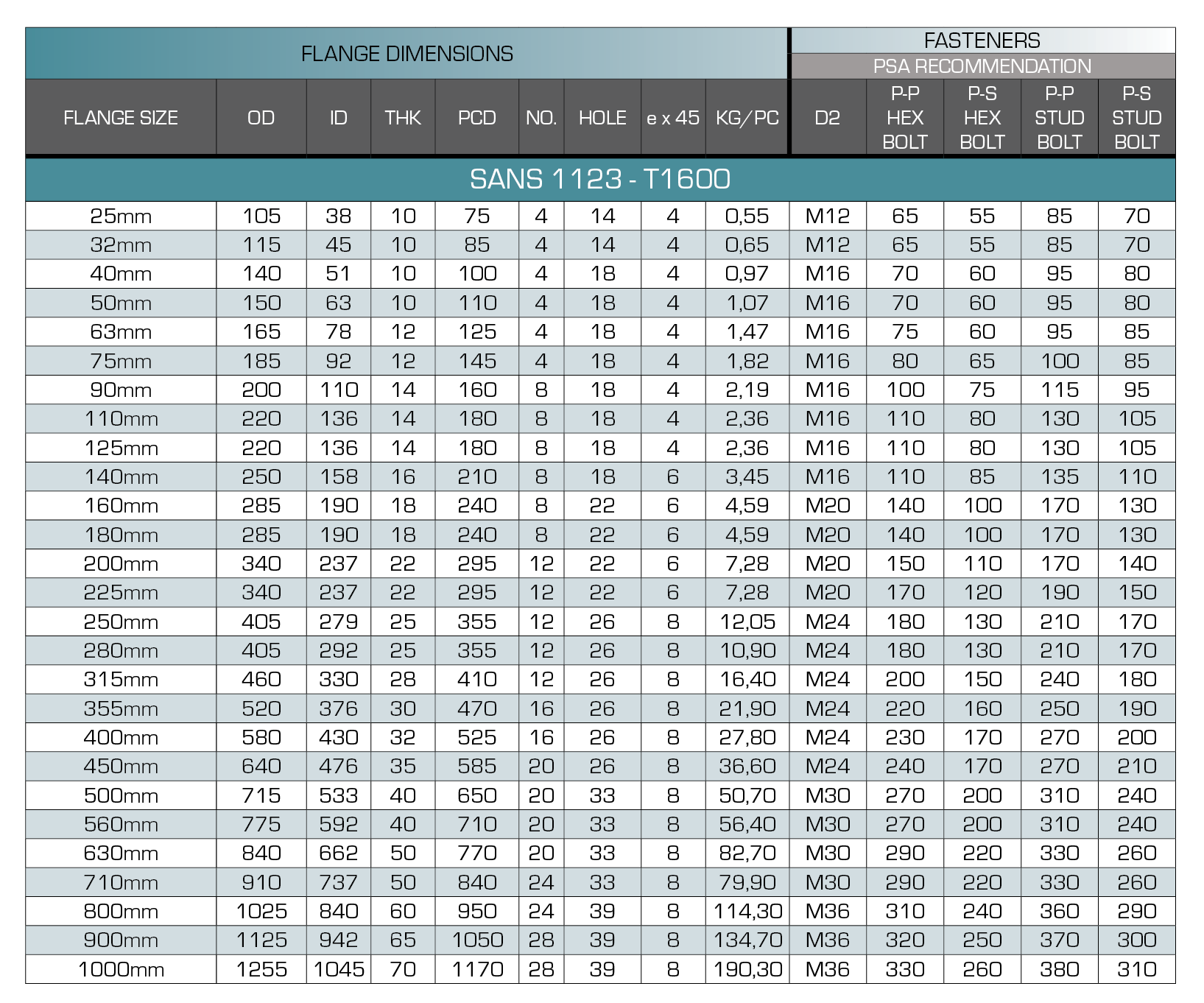

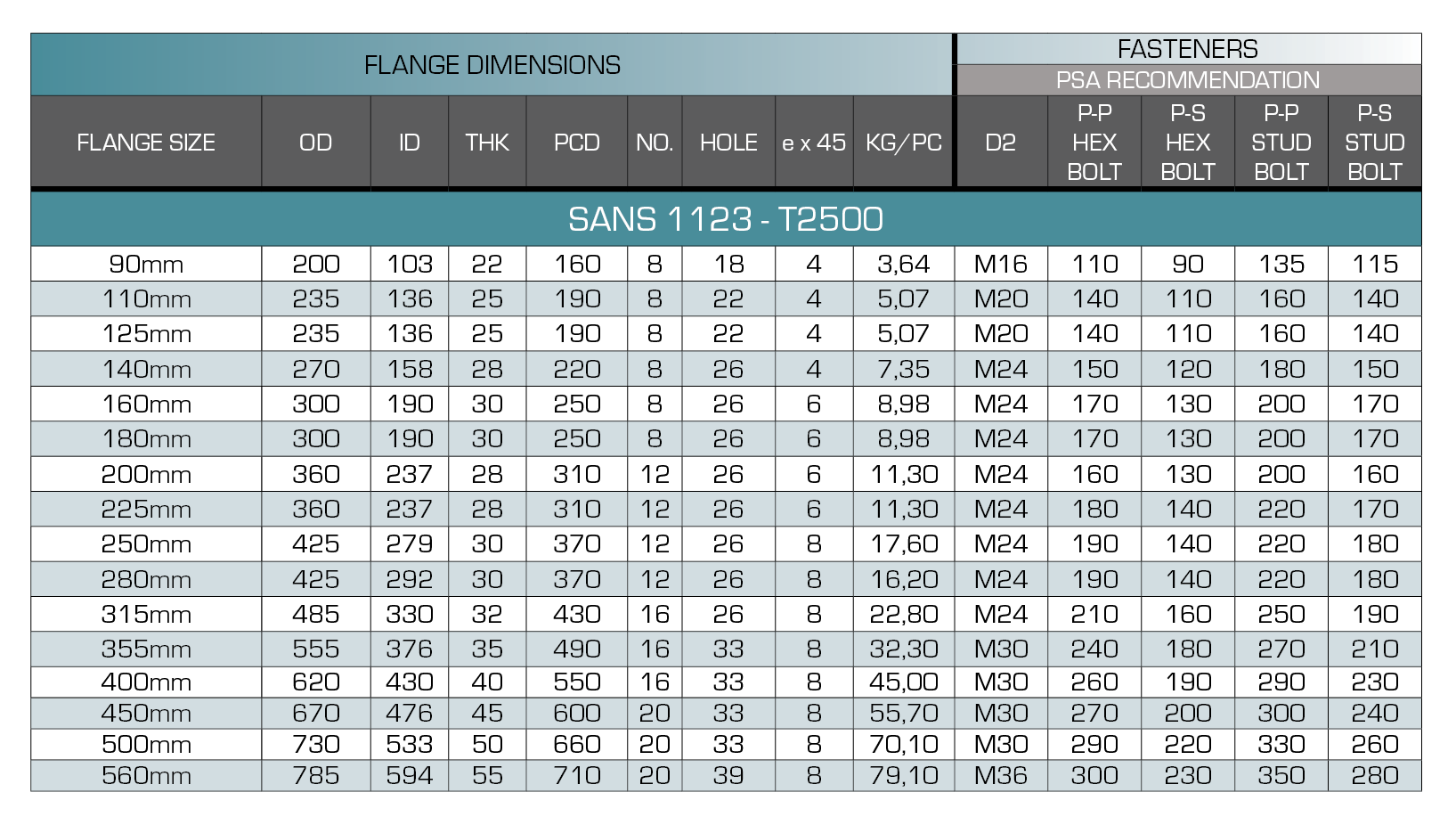

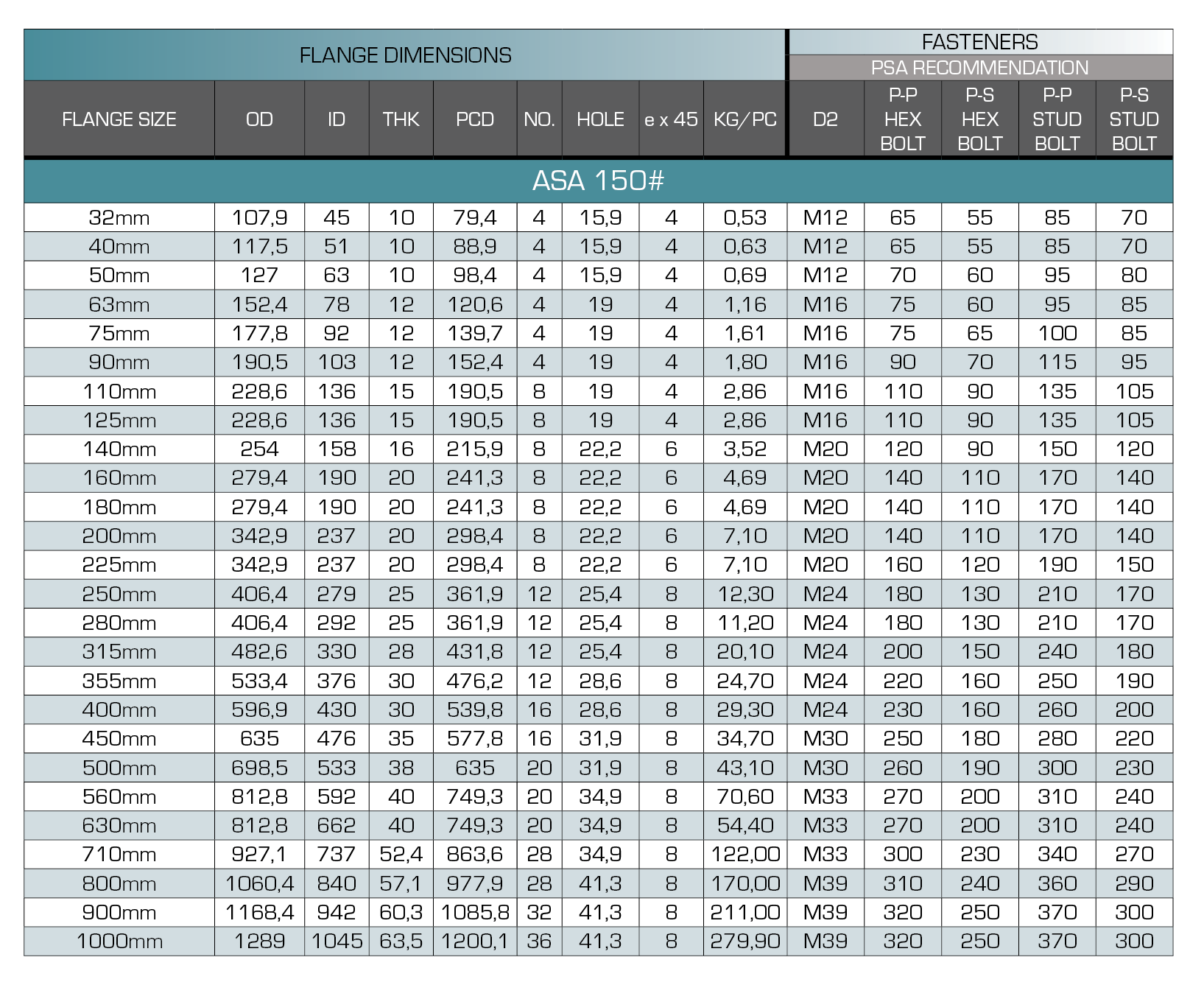

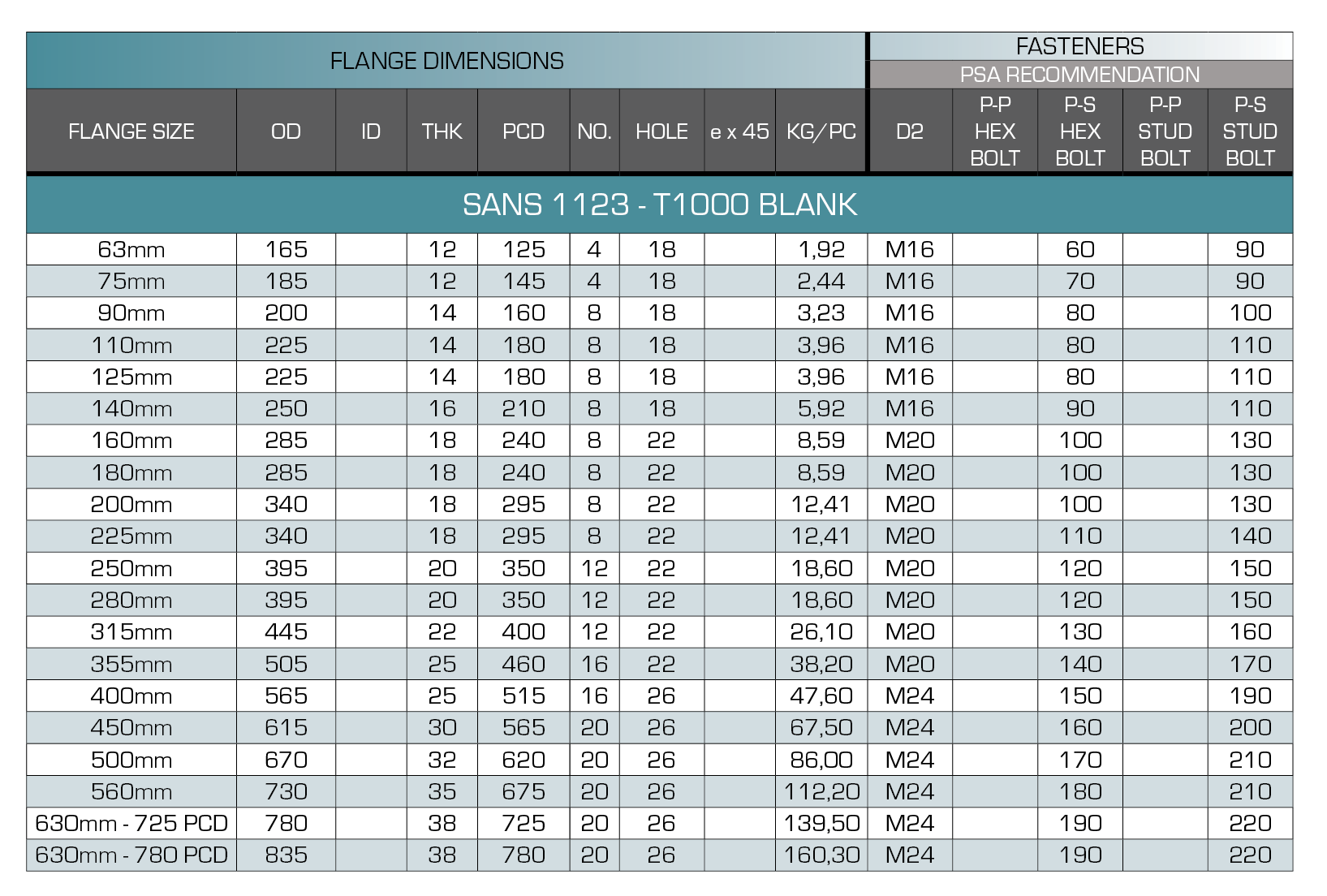

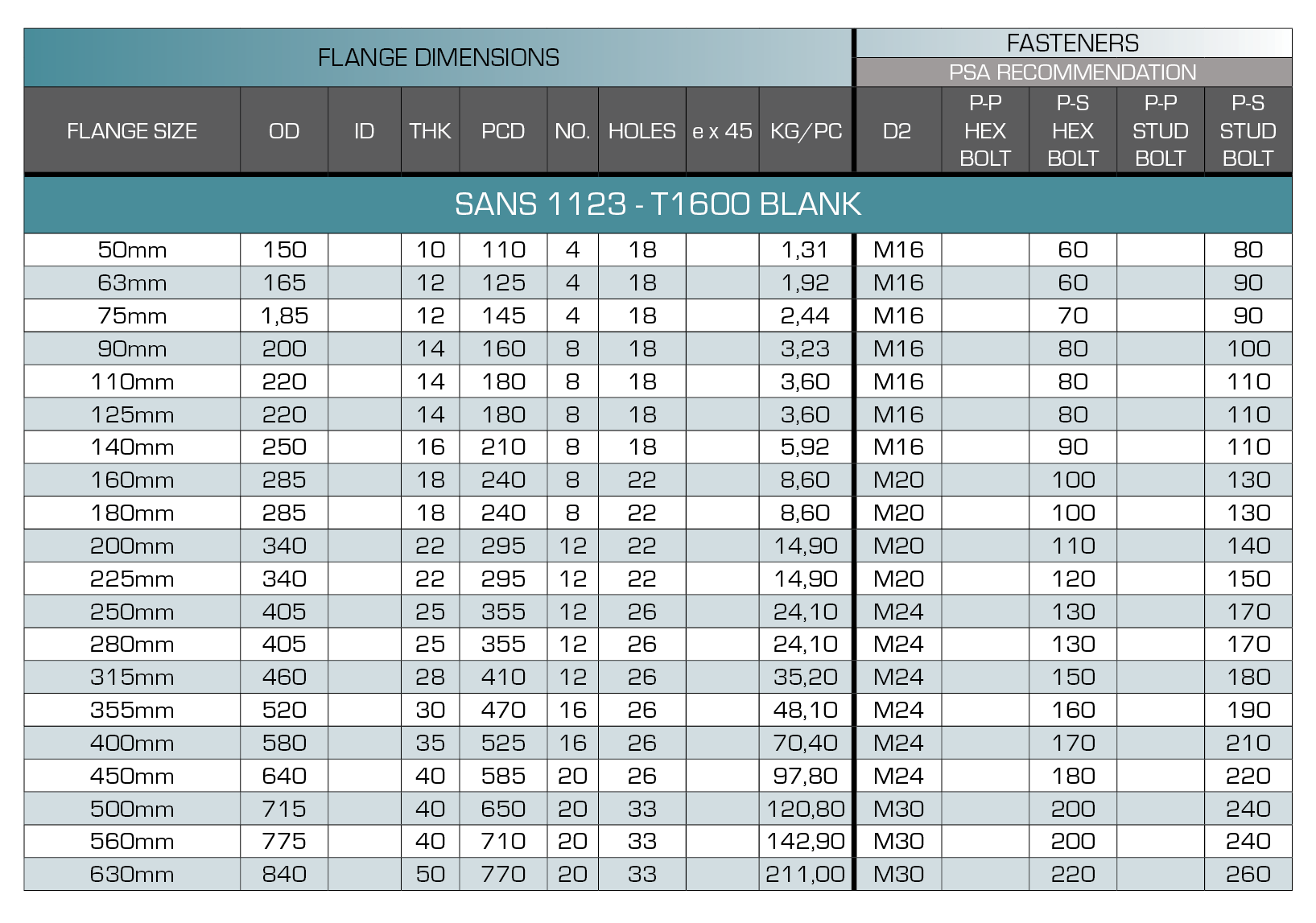

FLANGES

Carbon steel hot dipped galvanised

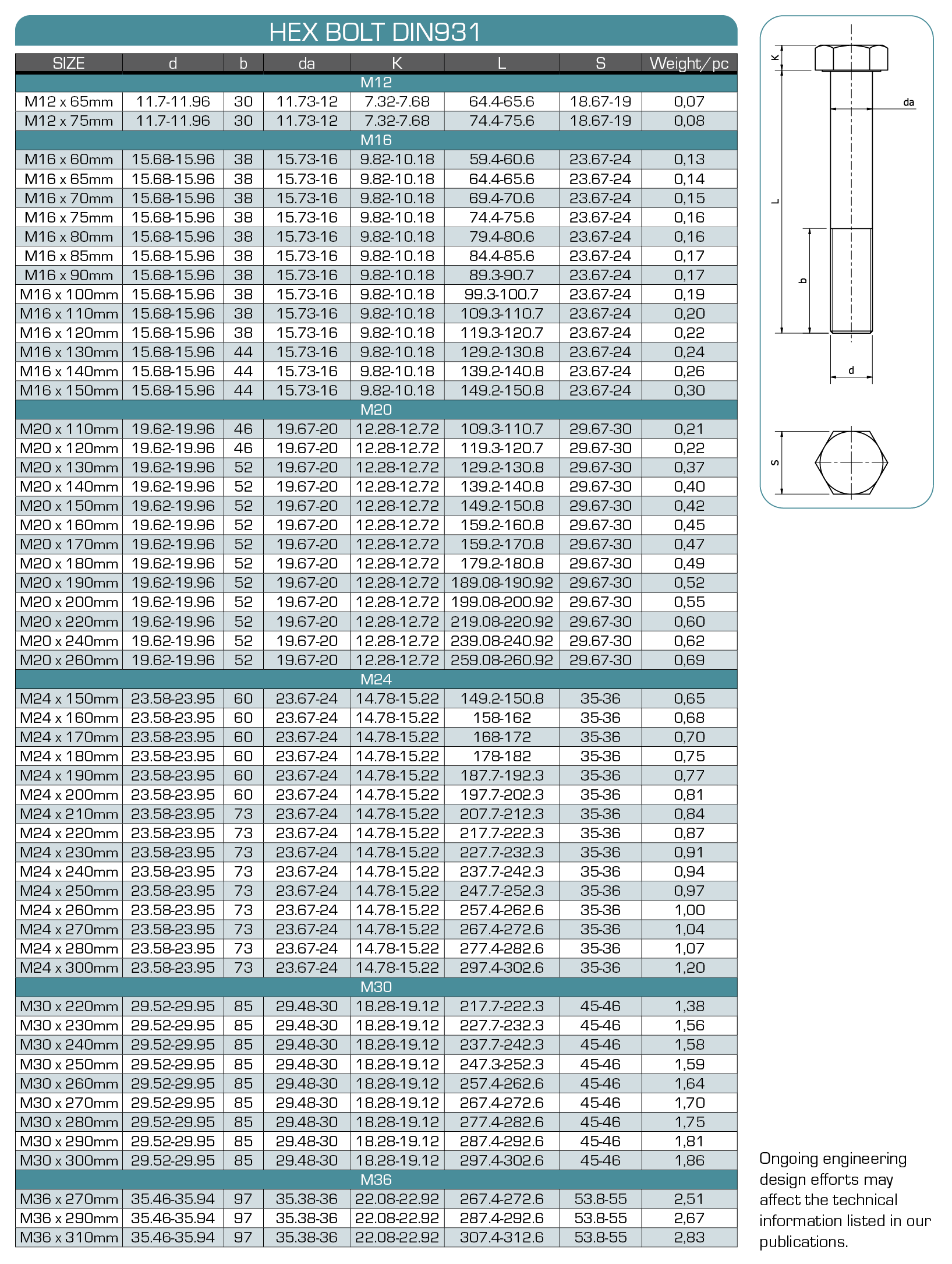

FASTENERS

Carbon steel hot dipped galvanised

CONTACT

22 Old Vereeniging Road,

Kliprivier, Midvaal, South Africa,1871

Tel: +27 87 655 4390

Email: info@pipestarafrica.com

Registration Number: 1964/006605/07

VAT Number: 4170232781