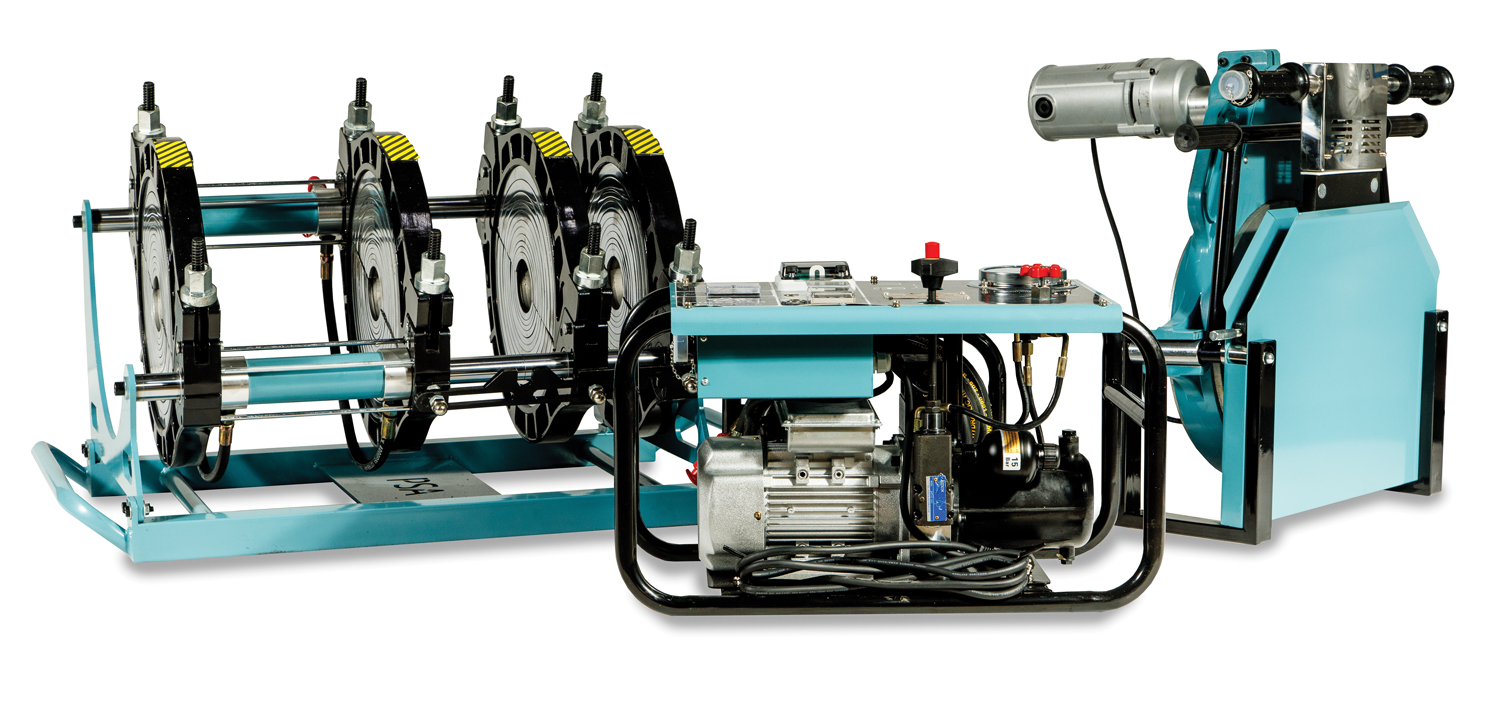

Hydraulic

Butt Welding Machine

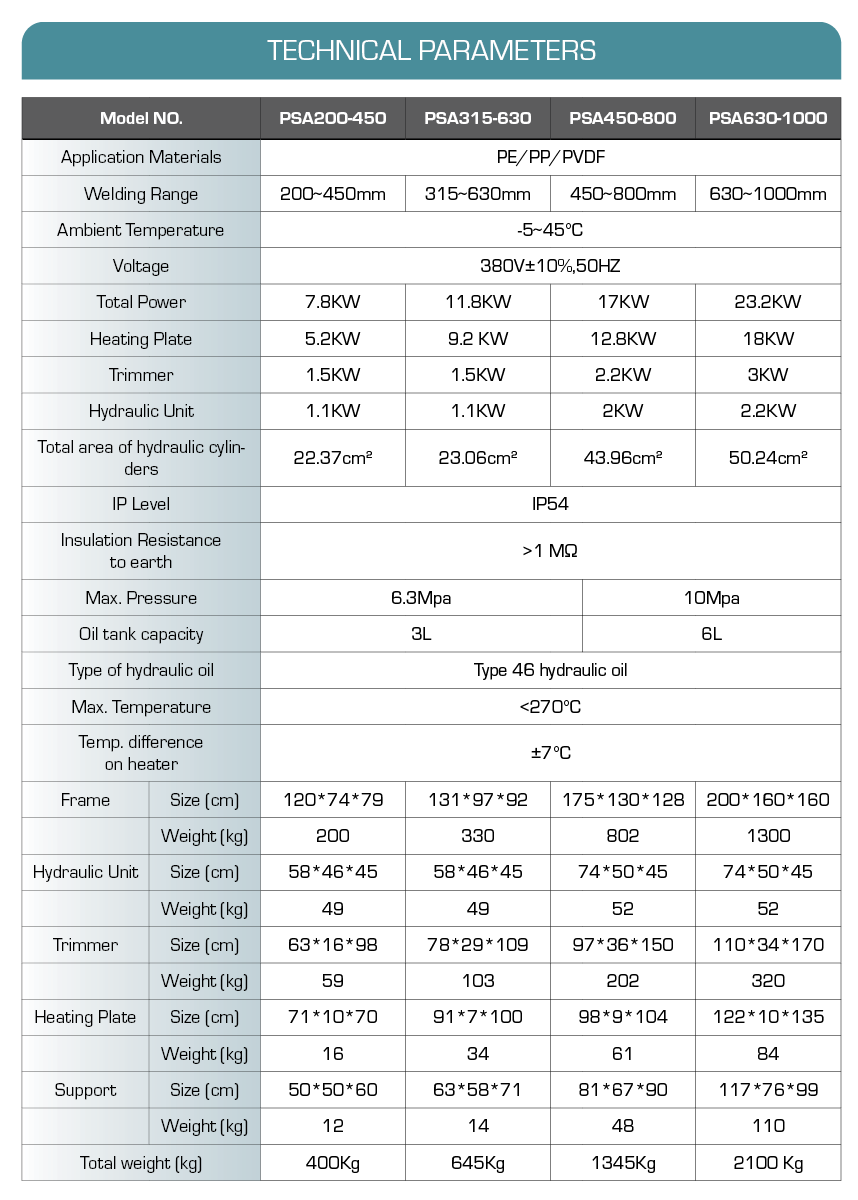

Our range of hydraulic Butt Welding machines include:

PSA 40 – 160

PSA 50 – 200

PSA 50 – 250

PSA 90 – 315

PSA 90 – 355

PSA 200 – 450

PSA 315 – 630

PSA 450 – 800

PSA 630 -1000

OPERATING INSTRUCTIONS

Before operating the machine, the user should read this user manual to ensure the equipment and operator’s safety, as well as the safety of others:

- The machine is used to weld pipes made from PE, PP, PVDF and should not be used to weld material that cannot be identified, otherwise the machine may be damaged, and accidents may occur;

- Don’t use the machine in a place with flammable or explosive hazards.

- The machine should be operated by responsible, qualified and trained personnel;

- The machine should be operated on a dry area. Protective measures should be adopted when used in wet conditions.

- Note that the Voltage of PSA160-PSA355 is 220V±10% / 50HZ ,Voltage of PSA400-PSA1000 is 380V±10% / 50Hz.

- Before using the machine, fill the hydraulic oil reservoir with 46# hydraulic oil. Make sure the hydraulic oil is sufficient for smooth operation. Replace the metal oil tank cap by the red plastic air bleed cap provided

The welding machine – should be operated by professional and certified personnel. Non-professional use of equipment may pose a hazard to operators and people around them.

Heating plate – The Heating plate temperature can reach 270°C, please take the necessary precautions to prevent burns such as wearing protective gloves. Once pipe heating is completed return the heating plate to the frame for storage.

Trimming Cutter – Before trimming pipe or fittings ends, ensure that pipe and fittings surfaces are clean in order to prevent damage to the trimmer blades. Once trimming is completed, the trimmer should be returned to the frame for storage.

Hydraulic Unit – The hydraulic unit should be placed so as to avoid a tripping hazard. Hydraulic seals should be inspected regularly to ensure that there are no leakages of hydraulic oil.

All debugging should be performed by a qualified professional.

Clamping Frame – Ensure that prior to welding pipe and fittings to be welded are properly seated and secure. Ensure screws that hold aluminium clamp inserts in place are properly fastened.

Crane Use – 315 – 630 / 450 – 800 / 630 – 1000.

Crane assembly should only be done by qualified and competent persons.

Download the PDF format here for detailed Instructions on Use

CONTACT

22 Old Vereeniging Road,

Kliprivier, Midvaal, South Africa,1871

Tel: +27 87 655 4390

Email: info@pipestarafrica.com

Registration Number: 1964/006605/07

VAT Number: 4170232781